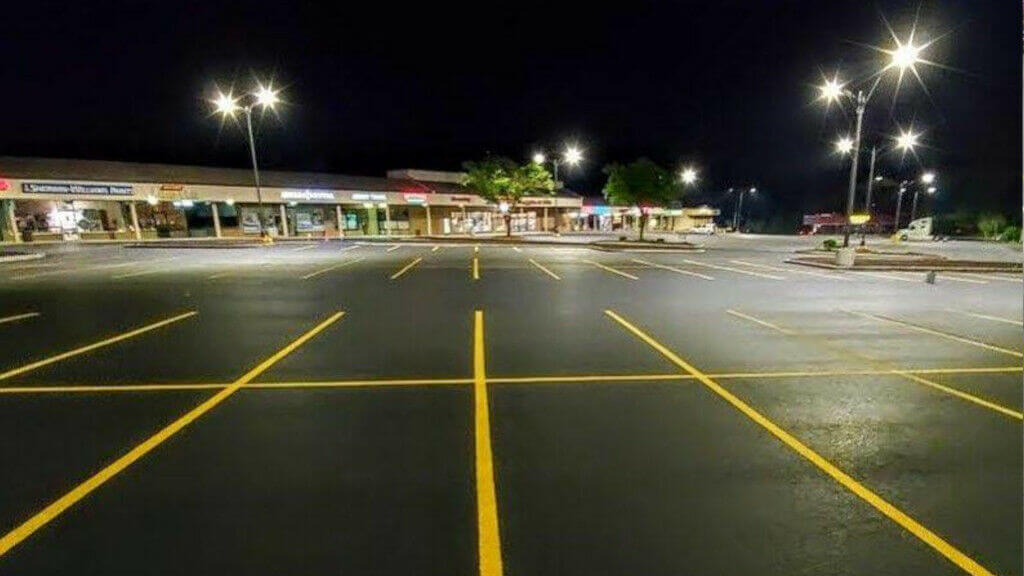

It’s easy to overlook the condition of your parking lot with all of the other business activities you have to attend to on a daily basis. If not properly managed, a parking lot can quickly deteriorate and become an unsightly mess, giving your visitors the wrong impression about your organization.

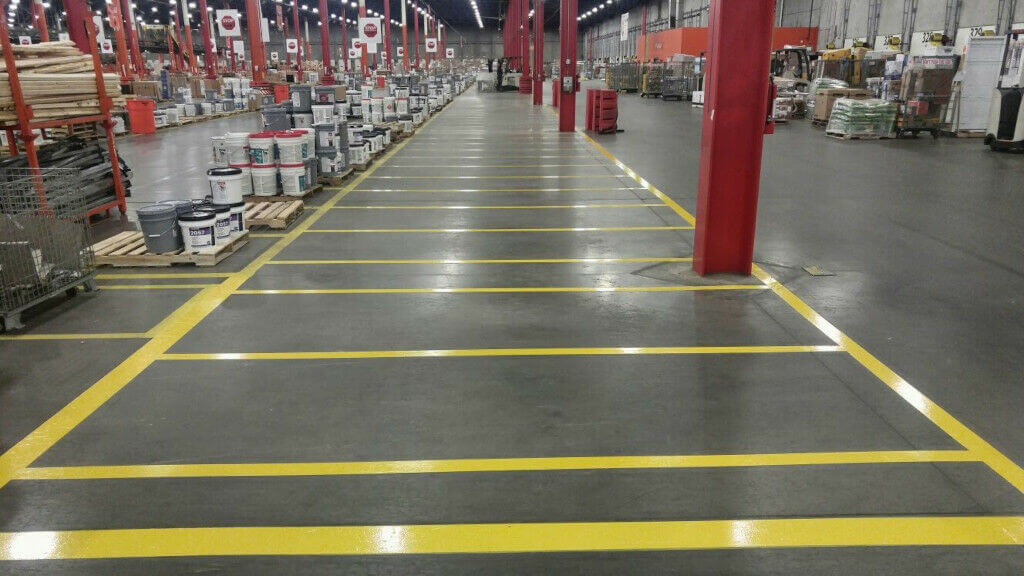

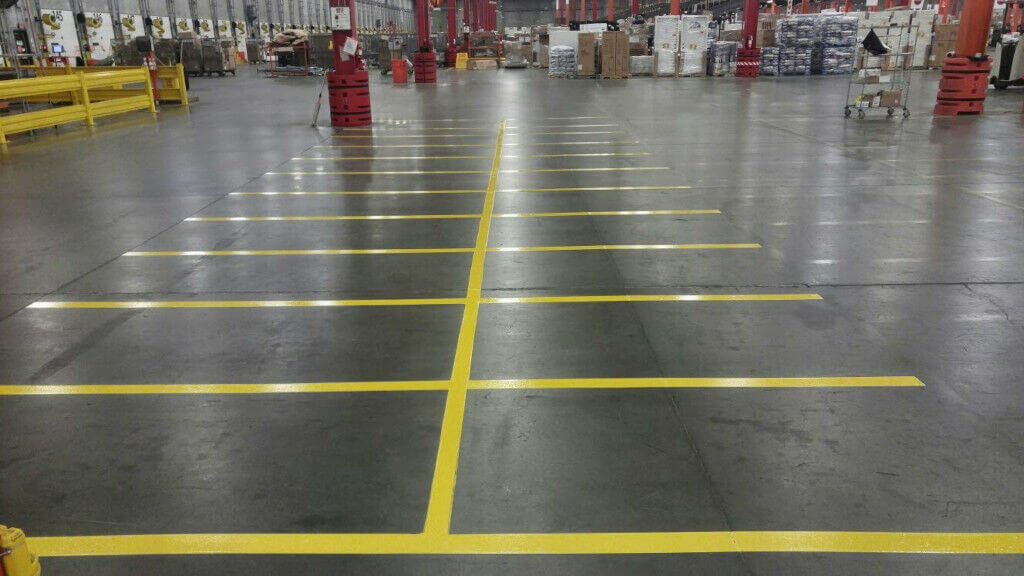

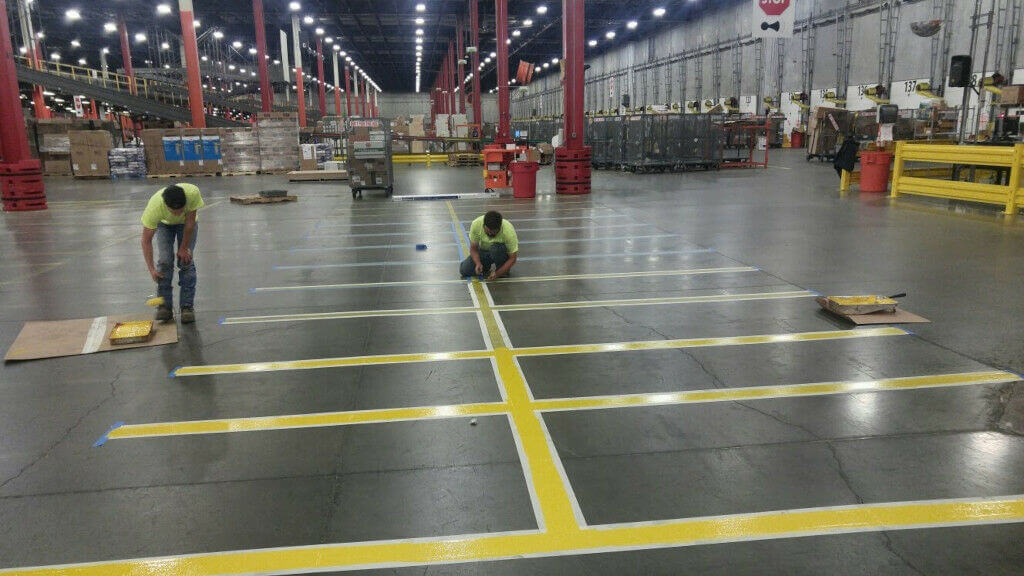

Badly maintained parking lots with fading parking lot line striping can create hazardous conditions by reducing visibility and making it more difficult for cars to stay in designated parking spaces while parking. Protecting your asphalt through seal coating and line striping should be a part of your routine maintenance and safety plan.

Protect Your Company’s Pavement With Sealcoating

To put it simply, asphalt pavement is made up mostly of rock, stone, and gravel, as well as a binder. This binder, also known as asphalt cement, holds the rock, or aggregate, together. The binder is made from various crude oils that have been distilled. Maintaining this binder is critical for preventing asphalt surfaces from deteriorating.

Pavement, in reality, begins to wear down as soon as it is installed. Rain, ultraviolet radiation, and chemicals, when absorbed into the asphalt, will start to destroy the binder, causing the asphalt to disintegrate. This will continue as more time passes and is left untreated resulting in a brittle surface.

It is critical to establish a maintenance program that includes seal coating to decrease the impacts of these factors and to extend the life of your pavement.

Sealcoating will add a layer of protection against the elements, such as water, oils, gas, and UV rays. Sealcoating also offers a slip-resistant surface with a rich black finish that beautifies the parking lot or driveway.

Sealcoating the asphalt on a regular basis will more than double its life expectancy, saving you money in the long run. Rather than spending thousands of dollars on new pavement, it is more cost-effective to maintain it for pennies on the dollar per square foot.

Depending on wear, traffic, and weather, asphalt pavements should be seal coated approximately every two years. Sealcoating newly surfaced asphalt surfaces should be delayed until they have had enough time to cure. This process might take up to 90 days.